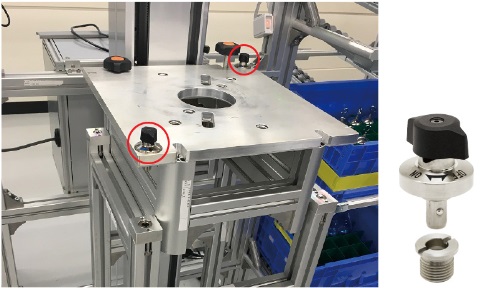

A customer designs and manufactures industrial tank gauges. They have succeeded in building an ergonomic production line to reduce the burden of workers and improve work efficiency by using Ball Locking Quarter turn on their assembly fixtures of tank gauges.

APPLICATION : Robotic workpiece clamping boosted production volume tenfold

Matsuura Machinery Corporation is a machine tool manufacturer that offers innovative technology worldwide. They use Spanclamps Torque automatic clamps in their fixtures for pallets and spindle housings of 5-axis machining centers.

APPLICATION : Spanclamps quarter turn provided quick and reliable fixture changing!

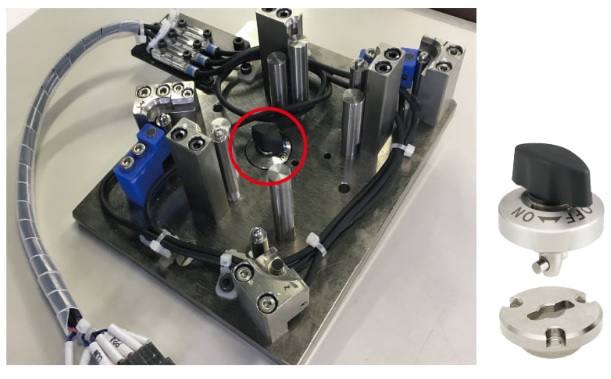

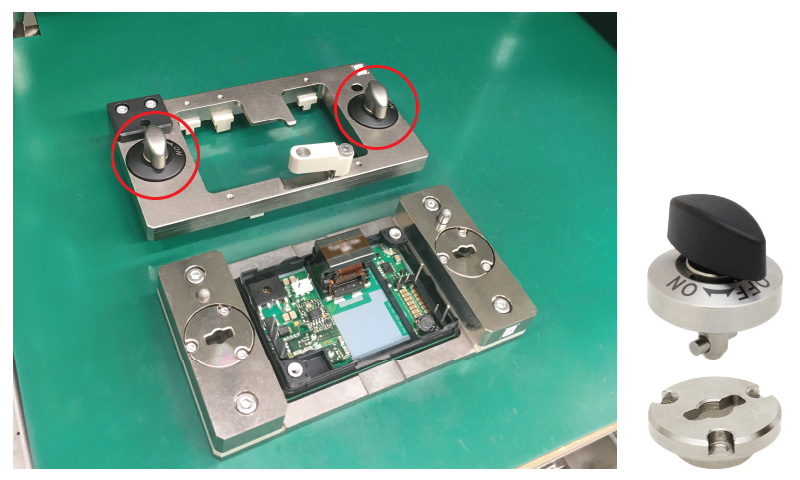

This customer develops control devices for automobiles worldwide and they use Spanclamps Quarter Turn Fasteners on assembly fixtures for motor actuators.

In the process of assembling the bracket to the actuator, they use four types of dedicated fixtures. The operator needs to change the fixtures every time the actuator to be assembled changes. They used to clamp the fixtures with wing screws, but it was not only troublesome to turn the screws many times, but also time-consuming to find the removed screws when they were lost.

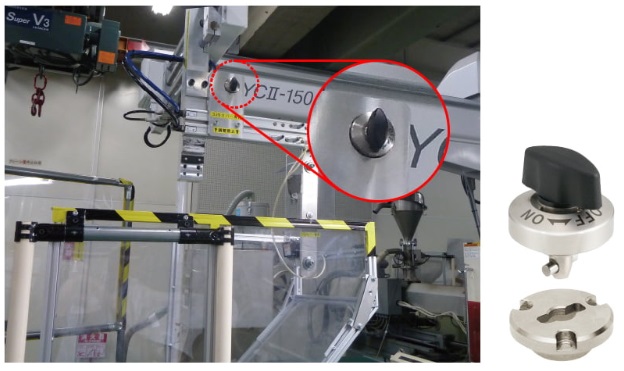

APPLICATION : How Quick & easy changeover in injection molding machine?

A manufacture of intercom and fire alarm for home use Spanclamps Quarter Turn SCQT on injection molding line for the resin products. They cut the resin burr on back of the post-molded products by a nipper.

Setups for changing the nipper and its position come out every mold change because the position of the burr is different product by product. In the previous line, they used the general-purpose nipper units for all products and it took more than 15 minutes to loosen screws, change nippers and adjust positions. They needed to change the mold more than 50 times per month for some machines.

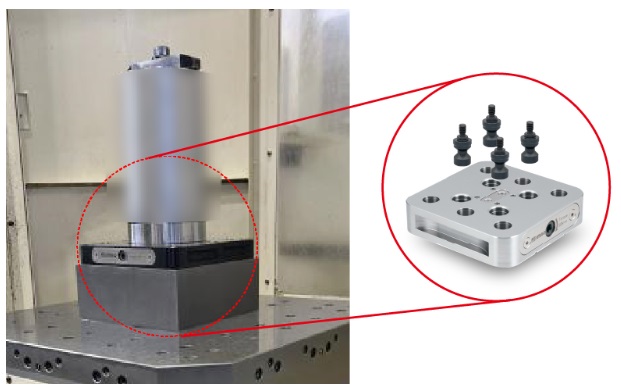

APPLICATION : Automation of centering optimized machine operating rate and labor force

Based on their philosophy of high precision and high efficiency, a customer uses a variety of selected equipment to machine single parts for automotive molds and machine components. They introduced Spanclamps quick accurate positioner Zero Base to reduce internal setup time in high-mix low-volume production on their new 5-axis machining center.

Previously, internal settings such as centering workpieces and fixtures were done manually. It took up to 20 minutes per set-up, even for a skilled operator, meaning that the machine had to stop during this time.

APPLICATION : How to change workpiece in 30 seconds on 5 axis machine?

A manufacture of die casting molds for major automobile manufacturers. They use Spanclamps Flex Zero Base to change fixtures on their 5-axis machining center. They produce mold parts made of tool steel in single part production with this 5-axis machining center.

Previously, operators had to stop machines for changing fixtures and mounting workpieces in the machine, once workpieces changed. It took 30 to 60 minutes to set up and this depressed machine operating rate. This was an issue.

APPLICATION : How improved work efficiency on automated meat packaging machine with Spanclamps retractable quarter turn?

A manufacturer of meat processing equipment, uses the Retractacle Quarter Turn to change the hands on their brand-new "Scorpion" an automated meat packaging machine. Scorpion automatically puts aligned slices of meat on food trays. The hands that carry the meat slices to the tray have to be changed at least once a day, when the shape of the meat slice is changed or for cleaning and maintenance.

APPLICATION : SpanClamps for precision centering and fixing

We love to hear (and see) how our parts are used. Thanks for the great video!

"We use Spanclamps for our project ‘’Continental’’.

It is a PSB mounting application in plastic housing using an electric press. There are three reasons why we need interchangeable nests.

We chose Anemo for precision centering and fixing."

See it for yourself:

APPLICATION : How Reduce costs and be free of maintenance?

A major worldwide manufacturer of off the shelf switch mode power supplies used to use self-produced clamps for clamping two plates.

Their production line was shut down a lot for repairing damaged clamps due to heat hardening.

Since they use quarter-turn fasteners, they reduced costs (by 70%!) and the clamps are maintenance-free (for over 2 years now)!

APPLICATION : From complicated changeover to simple and time saving assembling

Your company manufactures machine parts, and you use fixtures of automated production machines to mount screws to the machine part body. Have you ever considered using ball lock clamps and button lock pins?

Many applications require "changeovers" that involve changing and replacing about 10 times a day, as a machine produces many products of different shapes and sizes.

Consider the benefits by using One-Touch Fasteners.

Less workload = less cost!